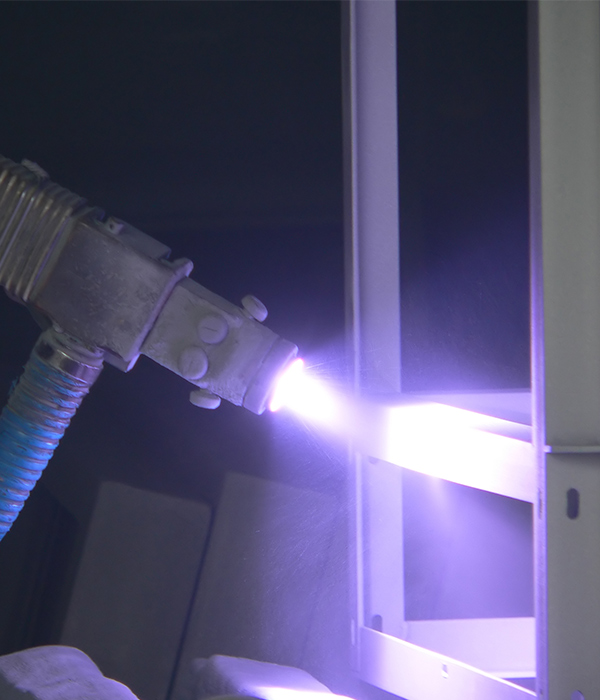

SPRAY GALVANIZING

Spray Galvanizing

Spray Galvanizing is a widely used surface coating technique to prevent corrosion of multiple materials. The most common application of this media is the use of zinc to protect iron substrates. Thermal spray coating offers excellent corrosion protection in moist conditions.

The spray galvanizing techniques at Mythri adhere to national and international standards applied as a corrosion protection restoration to damaged sections of galvanized, welded steel.

Transforming Galvanizing

Risk Free:

There is zero risk of heat distortion or weld damage of the surface.

Economical Process:

The spray galvanizing process is highly cost effective and economical.

Durable Structure:

The coating can act as a base and offer long life structures.

No Limitation:

The spray galvanizing media can support surfaces of any shape and volume.

Flexible Control:

The properties of the thermal spray coating can be controlled.

Catholic Protection:

The zinc Application forms a protective layer against corrosion.

Process

Blast Cleaning:

The surface of the metal is prepared by abrasive blasting with thorough cleaning and roughening.

Arc Spraying:

Zinc wire at a controlled rate is applied into an arc spraying process and the atomised metal impinges the coated surface.

Galvanizing

Zinc deposited follows a process through spraying in contrast to the conventional methods of galvanizing.