STRESS RELIEVING

Stress Relieving

Drawing, forming and machining induces stress. The treatment of a metal by heat process to a critical temperature of the metal which is the lower transformation temperature succeeded by controlled cooling.

Stress relieving heat treatment is a unique process of heating a metal under consistent temperature typically aiding in the removal of internal/residual stress accumulation.

Reduce the risk of dimensional changes such as loss due to forming, straightening, machining and rolling contributing to in-service failures like tolerance, cracking and distortion.

Transforming Stresses

The stress relief or heat treatment service at Mythri is performed with extreme heat treatment techniques considering the base material to achieve the desired reduction in the residual stresses of materials.

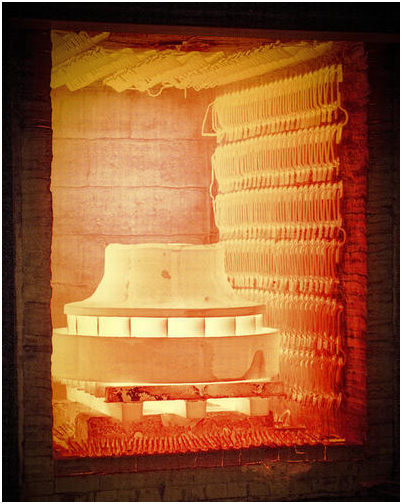

A typical stress relieving process starts with heating the material in an oven or furnace below the critical temperature. At times, stress relieving or heat treatment can be performed in a furnace with protective gas to protect surfaces from oxidation. Under extreme conditions vacuum furnaces can offer desired results.

Process

Heating

Stabilised temperature heat treatment to subject as per the class and volume of material.

Soaking

Allowing the material to soak for a certain time frame before the cooling treatment.

Cooling

Material is exposed to a slow cooling treatment to avoid the tensions caused by temperatures.